Pro built: Often the best choice with solid steel, which can weigh 50 pounds per linear foot, requiring heavy machinery to hoist it up. While this is the most time-consuming approach, the boxes are easier to transport with the average car. But these panels are available only in the most basic styles.

Ready to assemble: Building aluminum panels from a boxed kit by screwing pickets to rails drops the panel price to about $8 per linear foot.

Ameristar’s Montage is a rackable tubular-steel option, but more often, this type of fence panel is stepped down a slope.

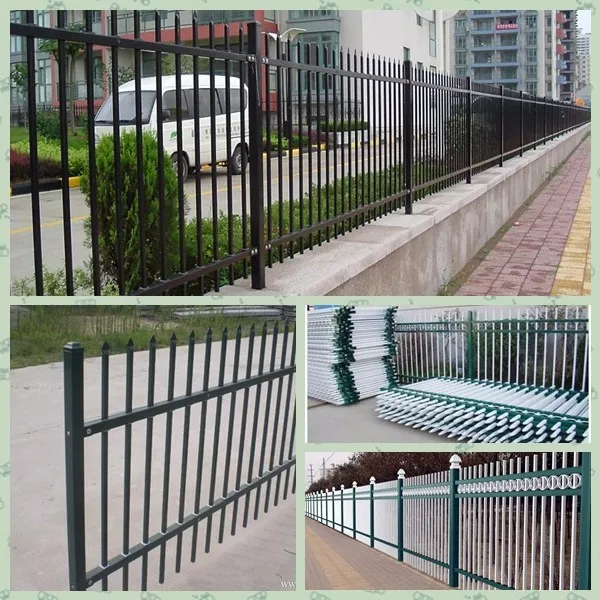

#Black steel fence install#

Because it’s stronger, steel comes in 8-foot panels, which makes it harder to transport, but you’ll install fewer posts. Hollow-steel panels are welded together or, in budget versions, joined with rivets, and can weigh about 50 pounds each. The screws joining the pickets to the rails allow you to “rack” the panel, following the slope of the yard. At 4-by-6-feet, panels weigh only about 11 pounds each but might require multiple trips to haul home. DIY-friendly home centers usually offer the best prices but a limited number of designs. Prefab: Home centers and fence suppliers carry 6-foot-long tubular-aluminum panels held together with screws. Purchase ready-made panels from a home center, build a DIY kit, or hire a pro to do all the work Cast ball finials top each hollow post, while staggered cast details add a pleasing rhythm to pickets welded to rails along the top and bottom. Shown: The simple lines of this solid-steel fence echo the understated style of a brick rowhouse. Some high-end manufacturers use molds to cast iron fence panels that feature shapes found in Victorian-era ornamental ironwork catalogs, but the product comes at a price-$125 and up per linear foot.įind out which type and style of fence will best flatter your house, while preserving your bank balance-and enhance the view from the curb. A custom fabricator can mix materials and manufacturing methods, depending on the budget, pairing cast-iron details with hollow-steel pickets that save on material costs. What is marketed as wrought iron today is often solid steel (though solid aluminum can also be found), dressed up with -machine-made scrolls and cast details, such as rosettes. When restoration projects call for true wrought iron, a craftsman has to rely on salvaged material that can be melted down to be reworked by hand, making genuine wrought-iron fencing prohibitively expensive. Even wrought iron’s classic glossy-black paint is upgraded with a longer-lasting, multistep powder-coating process that greatly reduces maintenance. The lighter-weight panels come together with fasteners, making installation easier. These days, metal fences aim to suggest traditional iron using more-available steel or weatherproof aluminum, usually with hollow pickets made to resemble solid 5⁄8-inch square bars. Such metalwork really peaked in popularity during the Victorian era, when foundries started casting and mass-producing elaborate pickets, posts, and scroll details. By the early 1800s, however, as blacksmithing grew domestically, ornamental iron began to embellish the more varied house styles of the day. In Colonial times, only the wealthiest could afford to import wrought-meaning hand-shaped-ironwork for their fine brick and stone townhouses.

0 kommentar(er)

0 kommentar(er)